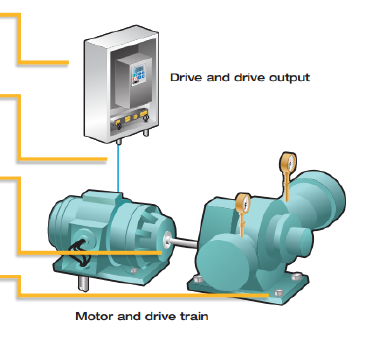

What to look for and how to improve asset uptime Motors are used everywhere in industrial environments and they are becoming increasingly complex and technical, sometimes making it a challenge to keep them running at peak performance. It’s important to remember that the causes of motor and drive issues are not confined to a single domain of expertise–both mechanical and electrical issues can lead to motor failure–and being armed with the right knowledge can mean the difference between costly downtime and improved asset uptime. Winding insulation breakdown and bearing wear are the two most common causes of motor failure, but those conditions arise for many different reasons. This article demonstrates how to detect the 13 most common causes of winding insulation and bearing failure in advance

IOT2

What to look for and how to improve asset uptime Motors are used everywhere in industrial environments and they are becoming increasingly complex and technical, sometimes making it a challenge to keep them running at peak performance.

FEATURES :

- Machine running status

- overall equipment efficiency

- PM check schedule VS status

- CNC & PLC parameter monitoring